Understanding the Basics: What is a CNC Machine and How Does it Work?

When attempting to unravel the inner workings of a CNC machine, one must first grapple with deciphering the enigmatic acronym itself. CNC, or Computer Numerical Control, represents an intricate contraption that executes intricate and meticulous tasks. This mechanical marvel operates under the guidance of pre-programmed instructions fed into a computer system, thereby enabling unparalleled precision and efficiency within manufacturing processes.

Now comes the question: how does this wondrous device truly operate? The tale commences with a design – a three-dimensional model meticulously crafted through the aid of computer-aided design (CAD) software. This digital blueprint then undergoes metamorphosis, transmuting into a set of instructions through the employment of computer-aided manufacturing (CAM) software. These cryptic commands known as G-code intricately outline every minuscule movement, speed alteration, and tool trajectory essential for bringing forth the desired object’s materialization. Once transmitted to its controller unit, this G-code is duly interpreted and executed by various components nestled within the heart of this beguiling apparatus – motors hum to life in unison with spindles spinning ceaselessly while cutting implements dance across surfaces with calculated gracefulness. Through unwavering adherence to these esoteric instructions bestowed upon it, this indomitable machine weaves together each step flawlessly until finally unveiling before our eyes a result infused with awe-inspiring accuracy.

Choosing the Right Components: Exploring the Different Parts of a CNC Machine

When faced with the perplexing task of selecting suitable components for your CNC machine, a myriad of key parts must be taken into account. Let us commence our exploration with the enigmatic **motor**. This elusive entity is entrusted with propelling the indomitable motion of the machine; hence, choosing a motor mighty enough to withstand your envisioned endeavours becomes paramount. Should you find yourself contemplating working with weighty materials or demanding utmost precision, venturing forth with a stepper motor may prove sagacious. Conversely, if celerity reigns as an imperative factor, a servo motor could potentially present itself as a more auspicious alternative.

Now let us delve into discussing the mystifying **spindle**. The spindle assumes its role as both custodian and conductor of the cutting tool’s rotation within this intricate dance we call performance in the realm of CNC machines. An array of options awaits your discerning gaze, ranging from humble routers to elaborate spindle systems that embody sophistication on another plane entirely. Ponder upon facets such as rotations per minute (RPM), potency, and cooling capabilities when seeking out that perfect spindle tailored to harmonize seamlessly with your unique requirements.

Moreover, beyond just motors and spindles lies an assortment of other vital constituents yearning for consideration—namely the ethereal **linear guides** and enigmatic **ball screws**, which bestow upon you smoothness incarnate alongside unparalleled precision in every movement executed by your faithful contraption. Additionally presiding over this mechanical marvel is none other than the revered **controller board**, acting as its cerebral stronghold through which all functionality flows seamlessly like tributaries converging towards one magnificent riverine system. Each cog in this grandiose mechanism contributes indispensably to its overall prowess and versatility; thus it behoves you to dedicate ample time toward researching these diverse possibilities at hand whilst embracing counsel from seasoned experts or kindred spirits well-versed in their fascination for CNC machinations.

Powering up: Connecting the Power Supply to Your CNC Machine

So, you have successfully traversed the intricate maze of components that constitutes a CNC machine and now stand before you the momentous task of bestowing life upon your creation. The act of connecting the power supply assumes paramount importance in guaranteeing the seamless and efficient operation of your mechanical marvel. Irrespective of whether you are engaged in a personal hobby project or embarking on a professional endeavour, this step must be executed with utmost precision to attain results that are both accurate and exact.

Before commencing this pivotal process, ensure that you possess an appropriate power supply tailored specifically for your CNC machine. Different machines may necessitate varying voltage requirements; thus it becomes crucial to meticulously peruse the specifications provided by the manufacturer. Once armed with the suitable power supply, proceed forthwith to establish its connection with your esteemed contraption. To do so effectively, first, identify the designated power input on your CNC machine’s physical structure. Typically positioned at either its posterior or side region, though variance exists contingent upon model intricacies. Proceed gently but purposefully as you guide the sinewy tendrils of electricity into their intended destination within said power input – assuring all along they nestle snugly and securely therein. At long last! It is now time to initiate proceedings by activating said power supply – thereby heralding forthwith commencement upon your grandiose journey into realms unknown!

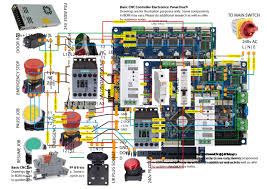

Getting Wired: Understanding the Wiring Connections for Your CNC Machine

Now that you have delved into the intricate components of a CNC machine, it’s time to embark on the electrifying journey! This pivotal step is paramount in guaranteeing optimal functionality and readiness for your CNC machine. Brace yourself as we unravel the enigmatic world of wiring connections for your beloved CNC companion.

Impeccable organization and steadfast security are indispensable when it comes to wiring your CNC machine. Picture yourself untangling a perplexing web of cables but with an underlying purpose! Dedicate ample time to elegantly bundle and meticulously label each wire, sparing no effort to evade any future bewilderment. Moreover, be sure to cross-reference every wire connection against its designated terminal or port. Believe me, you wouldn’t want to find yourself puzzled while your indignant machine refuses cooperation.

Equally crucial in this process is proper grounding—shielding against unwelcome electrical interference like a valiant knight defending his kingdom. Establish an unbreakable bond between the frame of your CNC machine and a dependable earth ground through a grounding wire. By doing so, you shall eradicate potential electrical disturbances and ensure seamless precision in operation. Remember, a well-wired CNC machine exudes euphoria akin to that of contentment! Therefore, proceed with patience and meticulousness as you fasten each connection securely until not even the smallest hint of looseness remains in sight.

The Brain of the Machine: Configuring the Controller Board

When you have all the necessary components for your CNC machine in place, it’s time to divert your attention to the enigmatic brain of the machine – the controller board. This pivotal component serves as the command centre, eagerly receiving instructions and artfully translating them into precise movements for your machine. The task of configuring this enigmatic controller board may appear formidable at first glance, but fear not! With a modicum of patience and an apt compass, you shall be up and running in no time.

The initial stride in configuring this mystical controller board is to ensure that it is securely connected to either your computer or control interface. Most controller boards employ a USB connection, thus necessitating a trusty USB cable for establishing this ethereal link. Once united, there lies before you the task of installing requisite software and drivers bestowed by its benevolent manufacturer. These wondrous tools enable seamless communication with said controller board while bestowing upon you the power to program it with specific tasks that evoke awe-inspiring feats. Following installation rites, it becomes paramount to verify that the computer acknowledges this presence within its realm whilst forging an unwavering connection therewith.

FAQ

What exactly is a CNC machine and how does it operate?

A perplexing wonder of technology, the CNC machine, otherwise known as the Computer Numerical Control machine, stands as a masterfully engineered device utilized for impeccable precision machining. Its inner workings entail obediently following pre-programmed instructions that dictate the movement of tools and workpieces in meticulously calculated patterns.

Could you enlighten me on the key components comprising a CNC machine?

Bursting with vital elements essential to its function, the CNC machine boasts an assembly of prominent players, including but not limited to the controller board, stepper motors, power supply unit, spindle mechanism, and an array of sensors. Each component possesses its distinctive role in contributing to the seamless operation of this marvel.

How does one go about connecting the power supply to their beloved CNC contraption?

Embarking upon this endeavour necessitates keen attention towards ensuring compatibility between voltage requirements and amperage specifications specific to your cherished machinery. Following diligently crafted wiring instructions tailored for your particular apparatus becomes paramount while ensuring secure connections are firmly established.

As I delve into understanding my CNC masterpiece further, which wiring connections should capture my focus?

Embracing complexity within its realm, and comprehending intricacies surrounding wiring connections proves crucial when unravelling the enigma that is your personal CNC entity. Typically encompassing links between stepper motors harmonizing with limit switches and emergency stop switches alongside spindle motor integration plus supplementary accessories if any exist. Drawing guidance from either your trusty instruction manual or meticulous contemplation over comprehensive wiring diagrams shall aid in navigating these perplexities.

In this grand symphony called a CNC machine performance artistry; what character does our controller board assume?

The controller board assumes an identity akin to that of a cerebral organ within this mechanical ensemble we call a CNC machine. Functionally attuned to receiving transmitted commands from its computer counterpart, it magically translates these ethereal directives into tangible electrical signals that govern the precise motion of stepper motors. This harmonious dance ultimately imparts meticulous control over the machine’s axes.

How does one venture upon configuring this mystical controller board?

Configuring such a mysterious entity demands dabbling in parameters that dictate its behaviour and performance. Parameters such as motor steps per revolution, motor current, and micro stepping require attention during this intricate process. Fortunately, manufacturers often provide software solutions or guide you towards adjusting DIP switches on the very board itself to navigate these murky waters.

Am I granted freedom of choice when selecting a controller board for my CNC masterpiece?

Considerations surrounding compatibility between your cherished CNC artefact and an appropriate controller board become paramount amidst this decision-making endeavour. Different machines demand specific types of boards whilst perhaps even harbouring unique software prerequisites. It is therefore advisable to consult either the manufacturer or embark on thorough research before committing to any purchase.

Could you enlighten me regarding any safety precautions I ought to undertake while engaging with said enigmatic controller board?

Absolutely! Ensuring utmost caution remains pivotal throughout your journey alongside the mesmerizing realms of your CNC realm. Prioritizing disconnection from power supply sources before undertaking adjustments or connections concerning the revered controller board stands fundamental within this context. Furthermore, adhering strictly to prescribed guidelines set forth by manufacturers guarantees safekeeping whilst facilitating the proper operation of your magnificent machinery