What is CAD software for CNC machine design?

CAD software, a pivotal component in the realm of CNC machine design, serves as an indispensable tool. Its capabilities allow engineers and designers to generate intricate digital models of their machine designs before physical production. With CAD software at their disposal, they can effortlessly visualize, modify, and optimize complex designs.

The paramount advantage of CAD software lies in its capacity to accurately simulate real-world conditions and interactions. Designers can seamlessly test diverse design iterations, delve into a myriad of materials, and scrutinize the functionality of their CNC machines—all without resorting to physical prototyping. This not only economizes time and resources but also empowers engineers to detect and resolve any potential issues or constraints before embarking on the manufacturing process itself. The prowess of CAD software enables designers to fabricate innovative, efficient, and dependable CNC machines that perfectly align with the specific demands imposed by their intended applications.

As technology forges ahead unabatedly, CAD software has experienced a progressive shift towards user-friendliness and accessibility. Presently encompassing an assortment of options ranging from rudimentary 2D drafting tools to sophisticated 3D modeling programs; these versatile software packages harbor not only an abundance of potent features but also boast intuitive interfaces that render the design process more gratifyingly streamlined. With CAD software’s assistance, designers are unshackled creatively while simultaneously pushing the boundaries inherent within CNC machine design—transmuting abstract visions into tangible realities. Anticipate delving deeper into this subject matter as we proceed onto our subsequent section wherein we will meticulously explore the salient features offered by CAD software.

What are the key features of CAD software?

CAD software, also known as Computer-Aided Design software, offers a myriad of crucial functionalities that are indispensable for the efficient and accurate design of CNC machines. Among these impressive capabilities lies the ability to generate intricate and meticulous 2D and 3D models. This empowers designers to grasp their visions through lifelike and immersive depictions. By harnessing sophisticated modelling tools, CAD software grants engineers the power to effortlessly manipulate and refine their designs, ensuring an optimal amalgamation of functionality and aesthetics.

Moreover, CAD software bestows upon its users a diverse array of instruments for drafting and annotation, facilitating lucid and succinct communication of design intentions. This fosters effective collaboration amongst designers and team members alike, paving the way for seamless synchronization in implementing alterations to the design. Additionally, CAD software boasts extensive libraries replete with pre-existing components, standard parts, as well as materials that can be readily assimilated into the blueprint. Not only does this expedite workflow but it also guarantees compliance with industry benchmarks alongside regulatory requirements. Overall, the pivotal attributes inherent in CAD software propel forward the design process by leaps and bounds while empowering designers to fashion intricate yet groundbreaking CNC machine designs with unparalleled precision eased by an air of perplexity

How does CAD software aid in CNC machine design?

The significance of CAD software in assisting CNC machine design cannot be overstated. It serves as a vital tool for engineers, equipping them with the necessary instruments to meticulously craft intricate and accurate digital representations of machine components. These three-dimensional models grant engineers the ability to perceive and manipulate the machine’s blueprint before it materializes into existence. This invaluable capability aids in uncovering potential design flaws or avenues for improvement, leading to the conservation of precious time and resources. Through CAD software, engineers can effortlessly alter designs, experiment with different configurations, and explore various functionalities of the machine, ensuring its performance reaches unparalleled heights.

One distinguishing feature that sets CAD software apart is its capacity to generate precise engineering drawings. These illustrations encompass critical information such as measurements, tolerances, and other indispensable specifications required for manufacturing machine components. By leveraging CAD software’s capabilities in this regard, manufacturers can rest assured that their produced parts adhere strictly to stipulated requirements without necessitating expensive rework. Moreover, sophisticated CAD programs often include simulation tools enabling engineers to conduct virtual tests and simulations under diverse operational conditions. This facilitates fine-tuning of designs while optimizing the overall efficiency and reliability levels of these machines—truly revolutionizing the CNC machining process by empowering engineers to conceive intricate designs with enhanced proficiency and exactitude.

What is CAM software for CNC machine design?

CAM software, an abbreviation for Computer-Aided Manufacturing software, possesses formidable prowess within the realm of CNC machine design. It stands as a digital marvel that furnishes designers and engineers with the means to forge meticulous directives for machines to dutifully obey throughout the manufacturing journey. On par with its counterpart CAD software, CAM software occupies an indispensable role in bridging the chasm between conception and actualization.

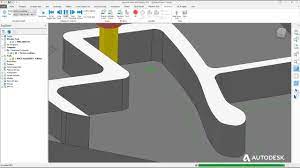

To CNC machine design, CAM software dons a myriad of pivotal attributes that elevate both efficiency and accuracy within the manufacturing process. A prime instance is its capacity to generate toolpaths; this ingenious functionality endows the software with the ability to ascertain optimal routes for cutting tools to traverse—thus ensuring minimal wastage and errors while achieving desired shapes and dimensions. Moreover, CAM software bestows designers the opportunity to simulate every facet of machining operations, granting them unparalleled insight into potential predicaments before venturing forth into physical production. Emboldened by such capabilities and more, designers are fortified with unwavering precision and confidence as they transmute their abstract visions into tangible manifestations.

What are the key features of CAM software?

CAM software, an abbreviation for Computer-Aided Manufacturing software, presents a myriad of pivotal facets that heighten the CNC machine design process. Among the most momentous aspects lies its capacity to generate toolpaths automatically. This signifies that once you have fashioned your creation in the CAD software, the CAM software possesses the ability to ascertain the most efficient toolpaths for machining based on specified parameters. The advantages are twofold: it saves substantial time and exertion as there is no requirement to manually compute and input these toolpaths, thereby guaranteeing a seamless and faultless production process. Furthermore, CAM software offers users the liberty to customize toolpath strategies, allowing them to optimize their machining operations and attain desired outcomes. With just a few clicks of a button, options such as roughing, finishing or contouring toolpaths can be selected by specific manufacturing requisites. Such adaptability empowers CNC machine designers to fine-tune their machining processes and achieve heightened precision and efficiency.

Another noteworthy attribute of CAM software manifests in its integration with simulation capabilities. Through harnessing 3D visualization technology, CAM software enables designers to virtually simulate the entire machining endeavour before executing it in reality. This feature affords designers ample opportunity to identify potential issues or errors before they materialize fully—a true boon that conserves both time and resources alike! By observing how tools interact with materials while simulating each step of the machining sequence meticulously, one can promptly spot any collisions or interferences within suboptimal tool positioning scenarios—thus enabling swift rectification measures accordingly. In so doing—voila! Your design is primed for optimum productivity whilst banishing costly blunders that might otherwise rear their ugly heads! Notably, this visual representation proffered by simulation features also aids greatly in assessing wear on tools—highlighting areas necessitating supplementary support or adjustment—and ultimately elevating overall quality standards about final machined products immensely! To conclude, the simulation capability bestowed upon CNC machine designers by CAM software proves invaluable—bestowing much-needed confidence and serenity of mind—and guaranteeing delivery of exceptional outcomes!

For additional information visit AutoDesk Fusion360

FAQ

What is the purpose of CAD software for CNC machine design?

CAD software, an acronym for Computer-Aided Design software, perplexingly serves as a computer application that burstily generates intricate designs and models for CNC machine components and products.

What are the fundamental characteristics of CAD software?

The fundamental characteristics of CAD software entail the capacity to meticulously fashion and modify 2D and 3D designs, ascertain precise measurements and dimensions, employ rendering and visualization tools proficiently, as well as ensure compatibility with assorted file formats and supplementary software applications.

In what ways does CAD software facilitate CNC machine design?

The enigmatic properties of CAD software significantly aid in CNC machine design by empowering engineers and designers to virtualize apparatus parts and scrutinize their functionality through meticulous testing procedures, while simultaneously permitting adjustments before fabrication. This multifaceted approach substantially curtails errors plaguing manufacturing processes, and optimizes efficiency levels considerably, all while ensuring impeccable accuracy within the final product.

How would one define CAM software concerning CNC machine design?

CAM software or Computer-Aided Manufacturing evokes an aura synonymous with a program specifically devised to transform initial designs conceptualized via CAD into a comprehensive set of instructions intelligible solely by CNC machines. It efficiently engenders toolpaths crucial for machining endeavours while concurrently stipulating cutting speeds along with feeds required alongside optimizing tool utilization levels conducive towards efficient production outcomes.

What distinguishes CAM Software from its counterparts?

The salient attributes accounting for CAM Software’s uniqueness reside within automatic generation capabilities associated with toolpaths; simulation mechanisms meant to facilitate verification processes; potent post-processing functionalities responsible for generating code tailored explicitly towards individual machinery setups; support extended across diverse manifestations constituting various CNC machining operations; finally culminating in seamless integration potential alongside corresponding counterpart -CAD- expediting cohesive trajectories spanning from conception-to-production workflows seamlessly intertwined together.

Can CAM software function autonomously, devoid of CAD software?

Although CAM software theoretically operates independently by manually inputting design specifications, the prevailing convention predominantly involves deploying it in tandem with its complementary counterpart- CAD Software. The latter initiates the preliminary design process before exporting finalized blueprints towards its collaborative companion -CAM Software- thereby enabling instructions essential for machine production to be meticulously generated.

What range of CNC machines can be accommodated by CAM software?

Proficiently adapting to an expansive array encompassing diverse CNC machinery manifestations such as mills, lathes, and routers alongside plasma cutters and 3D printers; CAM Software nimbly caters to individualistic requirements intrinsic within each apparatus category while diligently optimizing machining endeavors under specific operational prerequisites.

Is the user interface of CAM software beginner-friendly?

Numerous instances exist wherein various iterations constituting contemporary embodiments encompassing diverse realms of CAM Software culminate in proffering interfaces replete with intuitive workflows thus rendering them undeniably user-friendly. It is important however that users possess fluency concerning CNC machining concepts along with a comprehensive awareness of idiosyncratic intricacies underpinning a particular machine’s capabilities so as to ensure optimal utilization across all features afforded by the aforementioned platform.

Can one simulate machining processes before actual production via the employment of CAM software?

Indeed, CAM Software often encompasses simulation mechanisms alongside verification tools which egregiously enable visualizing intricate nuances pervading throughout multifaceted machining operations antecedent towards their execution phase. Thus effectively facilitating identification procedures targeting potential issues, collisions or errors liable towards manifesting during substantive manufacturing undertakings.

Does compatibility extend across dissimilar file formats when employing CAM Software?

Most certainly! Compatibility forms an integral component pervasive within conventional frameworks characterizing contemporary renditions aligned alongside respective versions associated with diversified existing CAD software. File formats widely embraced across this landscape encompass but are not limited to the likes of STL, STEP, and IGES alongside DWG formats. Noteworthy indeed is how such flexibility expedites seamless importation along with the exportation of design files throughout multifarious software applications promulgating enhanced coherence levels within an elaborate ecosystem spanning multiple functions.